Food and Beverage

Food and Beverage

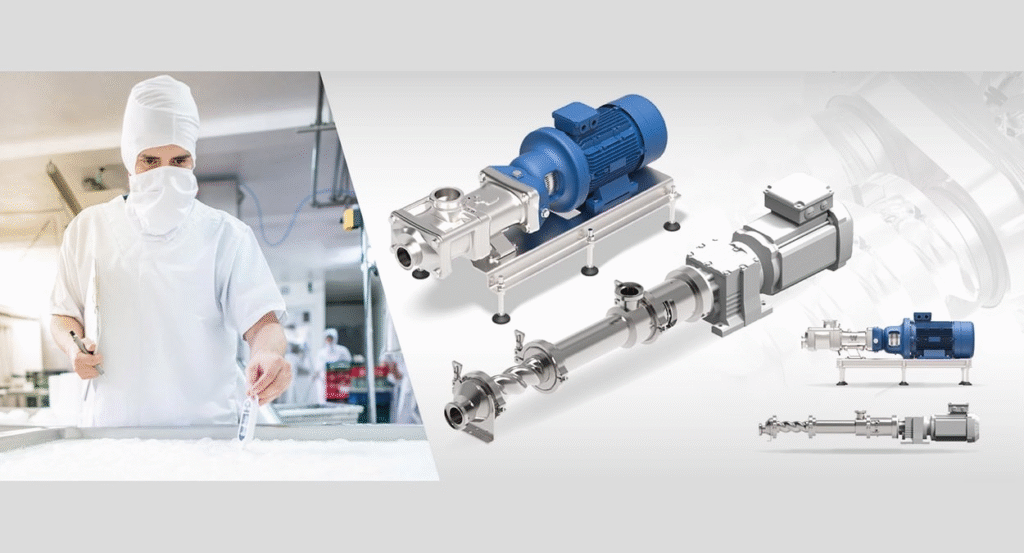

Food & Beverage

Industry Solutions

The food and beverage industry relies on pumps for a vast range of applications, from transferring raw ingredients and finished products to dosing cleaning chemicals. The success of a production facility is directly tied to the reliability, efficiency, and safety of these pumps. However, the unique characteristics of food products and the stringent regulatory environment present a number of significant challenges.

Key Pump Challenges in the Food

and Beverage Industry

Hygiene and Sanitation

This is the most critical challenge. Pumps must be designed to prevent the growth of bacteria and other microorganisms. This means eliminating "dead spaces," crevices, and other areas where product can stagnate. Pumps must also be easily cleaned, often through Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes. Failing to meet these standards can lead to product contamination, costly recalls, and severe damage to a brand's reputation.

Viscosity and Product Handling

The food industry handles a wide range of fluids, from thin liquids like milk and juices to highly viscous products like peanut butter, chocolate, and dough. A single pump may need to handle varying viscosities in a single production run. Pumping highly viscous fluids can lead to increased energy consumption, reduced flow rates, and high stress on the pump's components.

Shear-Sensitive Fluids

Many food products, such as yogurt, sauces, and delicate fruit pieces, are shear-sensitive. This means that excessive force or agitation during pumping can damage the product's texture, consistency, and appearance. High-speed, turbulent-flow pumps like conventional centrifugal pumps can ruin the integrity of these products.

Abrasion and Solids

Some food products contain abrasive solids like sugar crystals, fruit seeds, or grain particles. These can cause rapid wear on the internal components of a pump, leading to decreased efficiency and a shorter pump lifespan.

Clogging

The presence of solids, fibrous materials, or stringy substances can cause pumps to clog, leading to production downtime and the need for manual intervention, which in turn creates a risk of contamination.

The food and beverage industry requires pumping solutions that are not only robust and efficient but are also engineered with an unwavering commitment to hygiene and product quality. The shift from general-purpose pumps to specialized hygienic and smart technologies has been a critical evolution. By selecting the right pump technology and prioritizing a holistic approach that includes preventative maintenance and automated cleaning, food and beverage producers can ensure product safety, maintain operational uptime, and secure their brand’s reputation in a highly competitive market.

Nevtro’s Approach

sanitary standards for food processing.

minimize contamination risks.

downtime in critical production lines.